Olympus Hydraulic Control System

ARM – TruckCorp LLC knows the central hydraulic system and controls are the backbone of any truck build. We take meticulous care in building and installing these systems to ensure they are both durable and dependable while offering flexible design solutions that meet your desired operational needs. Systems are available in air over, cable control or electric actuated valves.

Monitor Usage

Keep track of your equipment’s location and receive notifications of any malfunctions.

Control

Six button joystick for seamless multi-function operation.

Save Money

Improve efficiency and optimize material usage with automated salt spreader modes.

Olympus System Features

Olympus Joystick

- Six button design that allows operator to switch between functions while operations are in use. No need to look at a screen or reach for separate buttons.

- Standard Joystick can control plow functions, flex plow, wing plow, body, belly scrapper, spreader blast and spreader pause all off the one joystick.

- Joystick has a dead man trigger to safely control all function from being accidently activated.

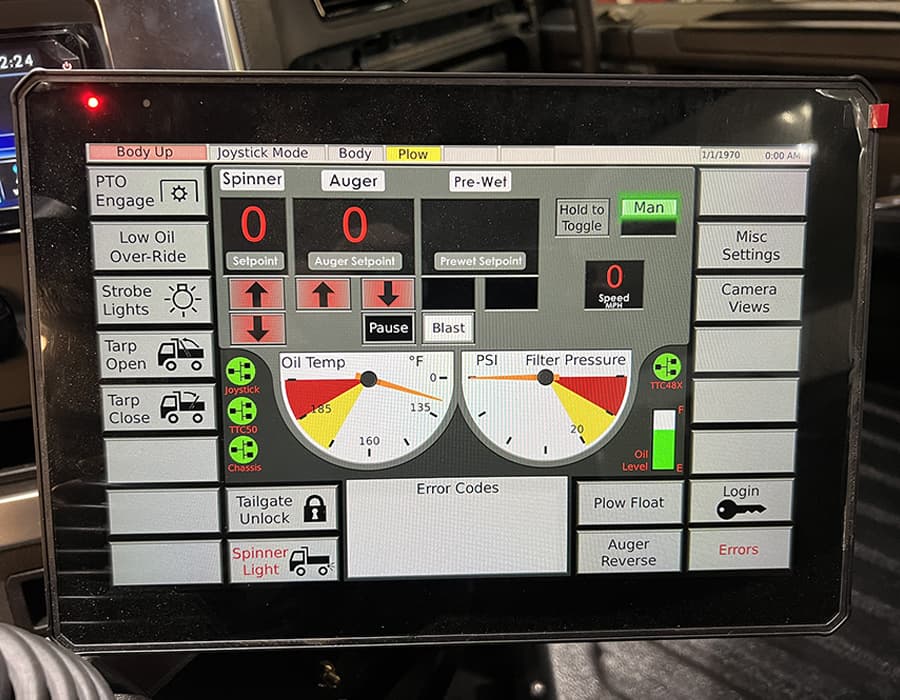

Touch Screen

- 12” full touch screen with automatic/manual brightness adjustment for operator comfort.

- Aluminum housing for a lifetime of durability.

- Password protected setting pages, ability to set trim levels, turn options on and off, and adjust power float strength.

- Home screen has real time telemetry to monitor system while in use.

- In case of a malfunction, the display will show error code and description of malfunction and troubleshooting suggestions.

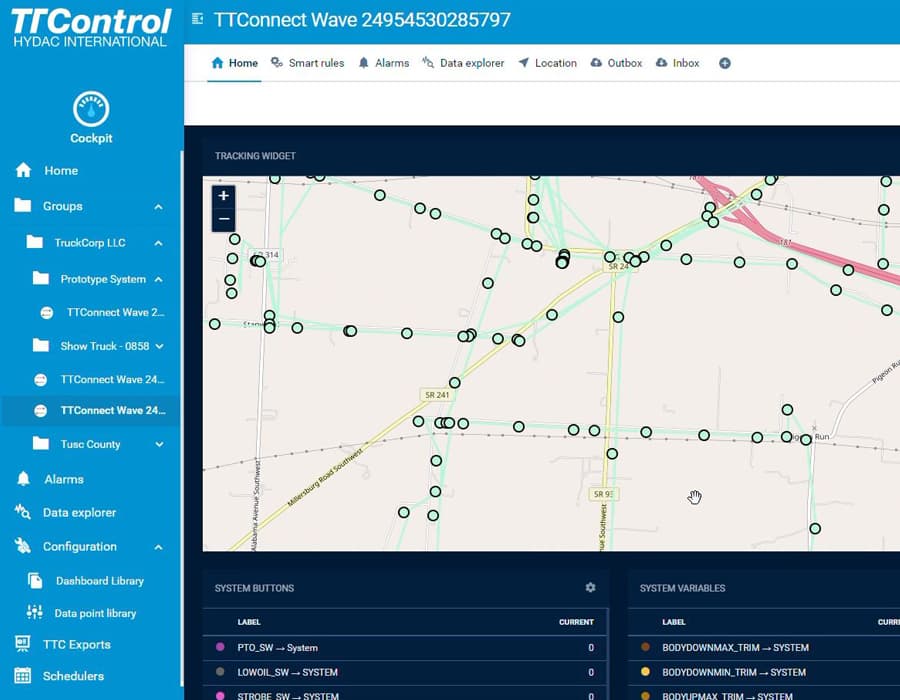

Telemetrics

- Monitors truck location every 60 seconds and stores the information.

- Send all information to the cloud and can be monitored at any time from remote location.

- Will send error codes and malfunction information to factory and supervisor email.

- Allow factory to diagnose the system remotely over the internet.

- Send and maintain service records and emails maintenance department of any needed service.

- Full Geofencing capability allows supervisors to fence in only areas where the spreader is permitted to operate.

Hydraulics

- Main valve is strong cast section valves with manual overrides and set screw stroke limiters.

- Six section main valve with a four section add on valve for optional equipment.

- Separate power float valve to control the float function on the plow.

- For weight reduction the system uses a plastic Tank that is only twenty-five gallons with internal baffles.

- Return filter utilizes patented metal housing, this design makes sure the filter does not crush like competitors paper style filters and maintains constant fluid flow. Filter is designed to keep fluid cool by not aerating hydraulic fluid.

Console

- Solid rear floor mounted pedestal with forward facing arms; with the pedestal mounted towards the rear it allows the truck floor to be open around the seat, and is a solid mount compared to the competitors pole style mount.

- Dual arms support the joystick and monitor, with the area under the joystick open this allows easy access to OEM dash functions like the park brake and dash switches.

- The console utilizes a seat bracket which allows the joystick to move with the seat, the operator’s arm and joystick are always in the same position in relation to each other.